Send Inquiry to This Product

Anti-corrosive FRP molded grating, the perfect solution for chemical plants. Crafted with utmost precision, this high-quality fiberglass grating is specifically designed to withstand harsh chemical environments, ensuring long-lasting durability and reliability.

Made from cutting-edge Fiber-Reinforced Plastic (FRP) materials, fiberglass grating offers unparalleled resistance to corrosion, chemicals, and extreme temperatures. Its robust construction ensures superior strength and load-bearing capacity, making it ideal for heavy-duty applications in chemical plants.

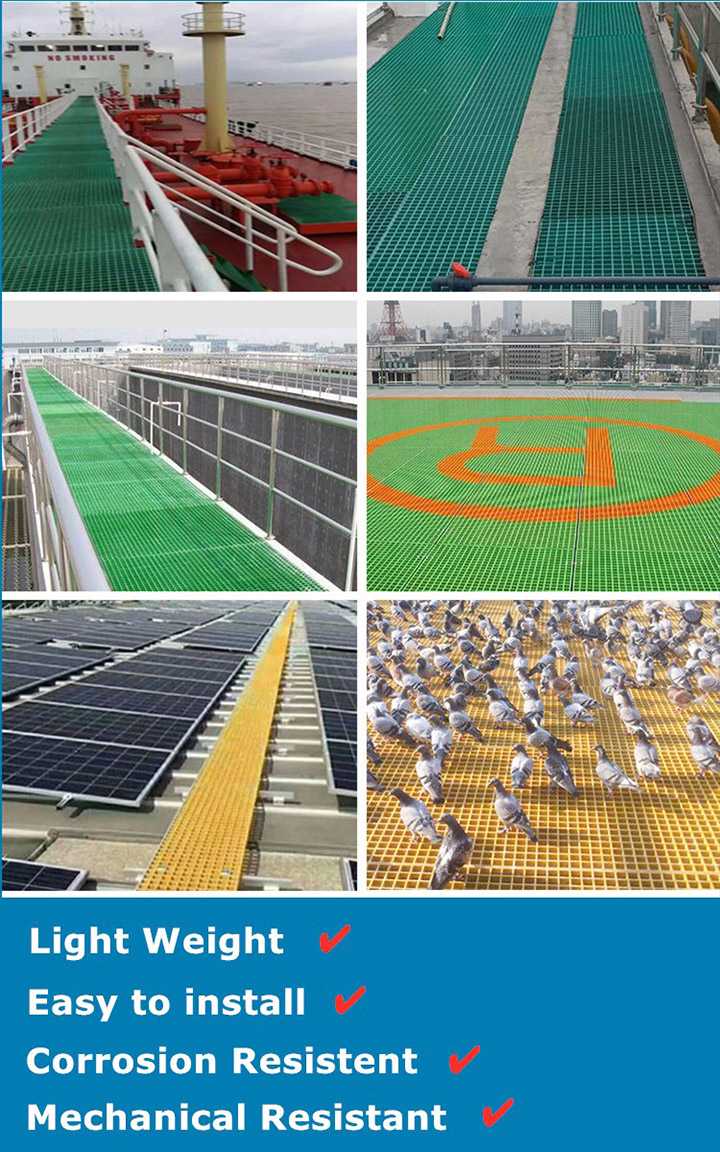

Compared to traditional materials like steel or wood, FRP molded grating provides numerous advantages. Firstly, its anti-corrosive properties eliminate the need for frequent maintenance and replacement, resulting in significant cost savings over time. Additionally, its lightweight nature makes installation quick and hassle-free, reducing labor costs and downtime.

Moreover, the non-conductive nature of FRP eliminates the risk of electrical hazards, making it a safer option for workers in chemical plants. The grating's slip-resistant surface further enhances safety by preventing accidents caused by slippery conditions.

The applications of anti-corrosive FRP molded grating are vast and varied. It is commonly used as walkway gratings, platform floorings, stair treads, and drainage systems in chemical plants. Its exceptional chemical resistance makes it suitable for use in areas where corrosive substances are present, such as storage tanks, processing areas, and laboratories.

With the increasing demand for corrosion-resistant materials in the chemical industry, the market for anti-corrosive FRP molded grating is expected to witness substantial growth in the coming years. Its superior performance, cost-effectiveness, and versatility make it a preferred choice for chemical plant operators looking to enhance safety and efficiency.

Invest in anti-corrosive FRP molded grating today and experience the unparalleled benefits it offers. Trust in its durability, reliability, and longevity to elevate your chemical plant operations to new heights.

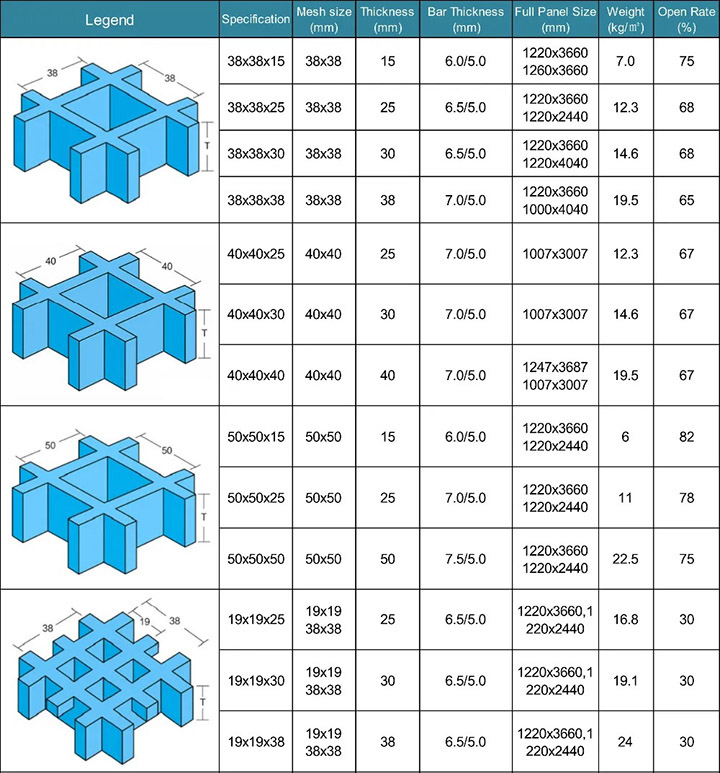

FPR Grating Types

Sizes & Specifications Available

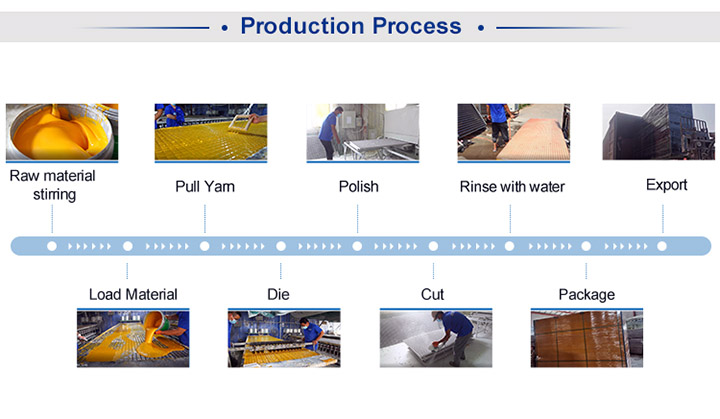

How Are FRP Gratings Manufactured