Send Inquiry to This Product

Corrosion resistant molded FRP grating is specifically designed to resist corrosion caused by exposure to chemicals commonly found in chemical plants. This type of grating is made from reinforced fiberglass materials, which are known for their exceptional strength and durability. It offers superior resistance to chemicals such as acids, alkalis, and solvents, ensuring the safety of workers and the integrity of the infrastructure.

WayTong is one of the leading providers in China for heavy-duty fiberglass gratings, we offer a wide range of options that meet strict industry standards and regulations.

Corrosion-Resistant Properties

Molded GRP grating is an essential component for ensuring safety and durability in chemical plants due to its corrosion resistant property. Designed to withstand harsh environments and corrosive chemicals, this type of fiberglass reinforced grating provides a reliable and long-lasting solution.

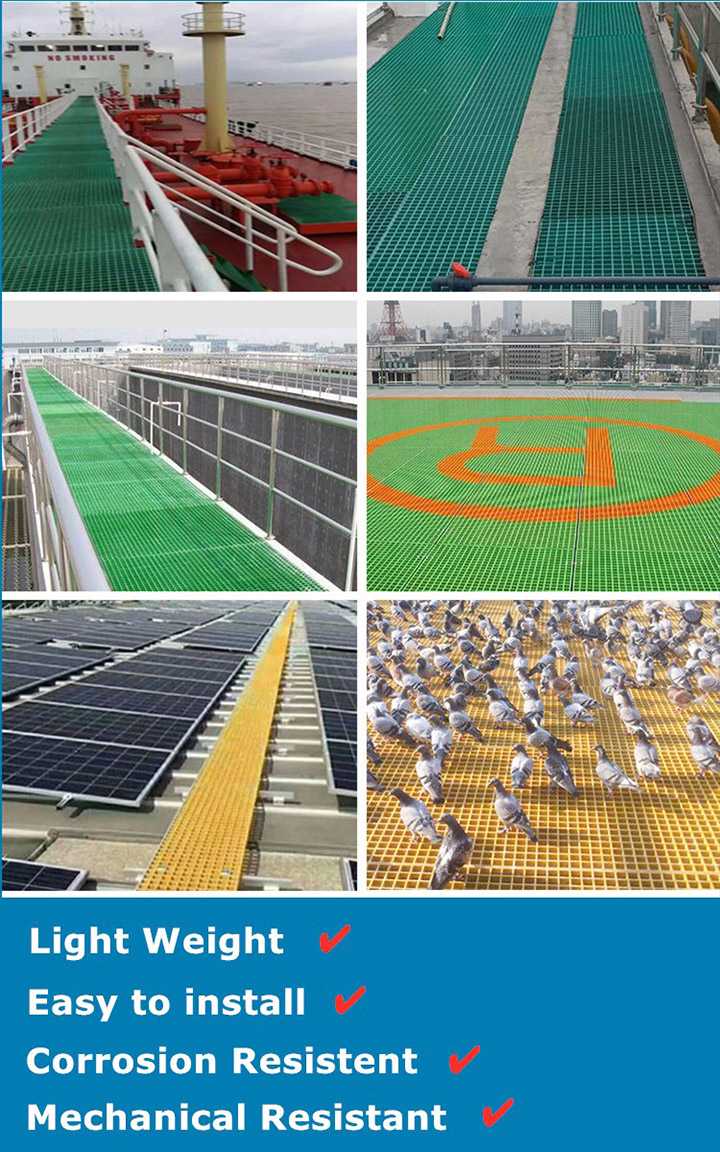

In addition to its corrosion resistance, fiberglass gratings also offer other advantages. It is lightweight, making it easy to install and handle. Its non-conductive properties make it ideal for applications where electrical conductivity is a concern. The open design allows for efficient drainage and ventilation, reducing the risk of slips and falls.

High Strength-to-Weight Ratio

One of the standout features of our FRP grating is its exceptional strength-to-weight ratio. This characteristic not only makes installation easier but also contributes to cost savings without compromising on durability and performance.

Chemical Resistance

The grating is engineered to resist a wide range of chemicals, acids, and alkalis commonly found in chemical processing facilities. This capability ensures that the grating maintains its structural integrity and safety standards even when exposed to aggressive substances.

Slip-Resistant Surface

Safety is paramount in industrial settings, and FRP gratings addresse this concern with surface gritted antislip gratings. This feature reduces the risk of accidents and enhances worker safety, making it an indispensable addition to any chemical plant environment.

Low Maintenance

Unlike traditional materials, fiberglass grating requires minimal maintenance, saving both time and resources. Its inherent resistance to rust, corrosion, and degradation minimizes the need for frequent upkeep, resulting in long-term cost efficiency.

How to Choose FRP Gratings

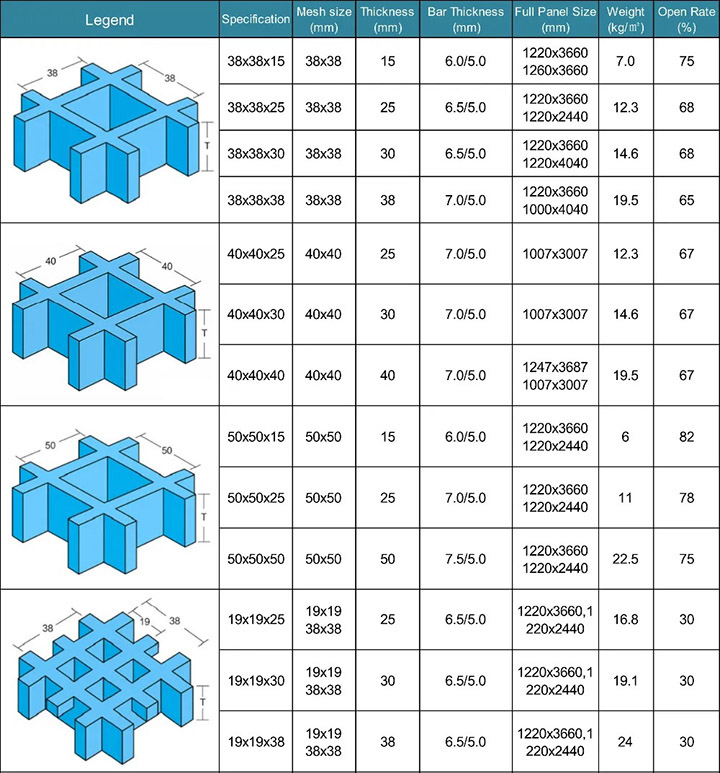

In a world, molded FRP gratings are corrosion resistant to chemicals, they are better than steel gratings as walkway and sewage covers in chemical plants. When choosing molded FRP grating for a chemical plant, it is important to consider factors such as load capacity, span, and mesh size. WayTong offers a variety of options to meet specific project requirements, ensuring that the grating can withstand heavy loads and provide a safe working environment.

Customization Options

We understand that each chemical plant has unique requirements, which is why our molded FRP grating can be customized to fit specific dimensions and load-bearing needs. This level of customization ensures that the grating seamlessly integrates into existing infrastructure while meeting all performance criteria.

FRP Grating Applications

FPR Grating Types

Sizes & Specifications Available

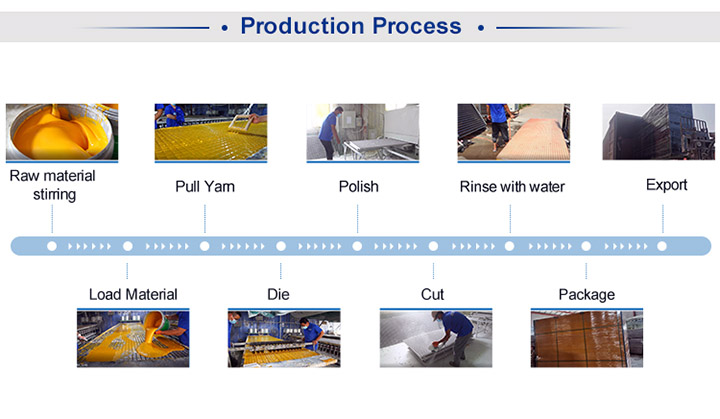

How Are FRP Gratings Manufactured